Manufacturers have been able to develop profiles that’re both strong and lightweight benefiting industries like aerospace, automotive and transportation where reducing weight is crucial for better fuel efficiency and performance.

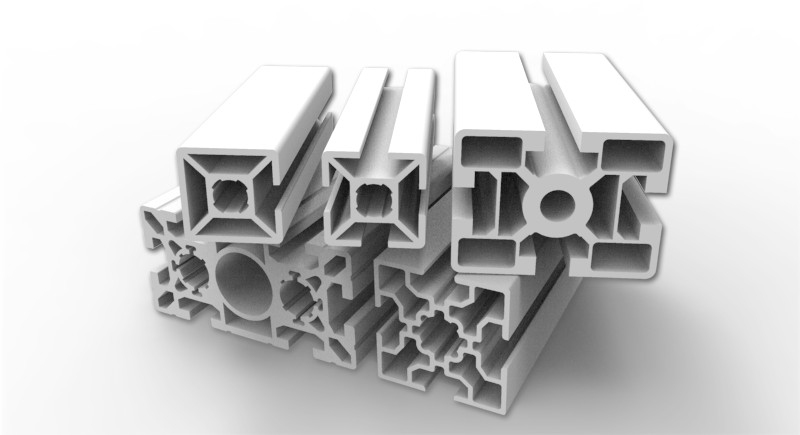

Aluminum profiles offer the advantage of being customizable to design needs. With advancements in extrusion technology profiles can now have shapes and complex geometries to enhance product performance while minimizing material waste.

Modern aluminum profiles can incorporate functionalities directly into the extrusion process, such as wiring channels and mounting surfaces. This integration streamlines assembly processes reduces component count. Improves efficiency.

Surface treatments and finishes for aluminum profiles have advanced significantly offering improved corrosion resistance well as a variety of colors and textures, for enhanced aesthetics and functionality.

Furthermore surface treatments are employed to adjust the friction, conductivity and other characteristics of the profiles to better suit uses.

Sustainability and Recycling

Aluminum is naturally sustainable due to its recyclability and low energy consumption in the recycling process. Advances in aluminum profile design have enhanced the sustainability of these products by optimizing material usage reducing waste and extending product lifespan. This supports initiatives to minimize environmental impact and foster a circular economy.

Utilizations of Aluminum Profiles and Components

Aluminum profiles and components serve industries, such as;

Construction; Utilized in building facades, curtain walls and structural framing.

Transportation; Found in automotive chassis, rail carriages and aerospace structures.

Electronics; Applied in heat sinks LED lighting fixtures and electronic enclosures.

Manufacturing; Used for conveyor systems, assembly lines and machine frames.

Renewable Energy; Employed in panel frames and wind turbine components.

Illustrative Examples

Automotive Sector

In the industry aluminum profiles are increasingly integrated to reduce vehicle weight and enhance fuel efficiency. Advanced extrusion methods enable manufacturers to produce lightweight sturdy structural elements, for car frames, chassis parts and body panels.

Automakers rely on this technology to meet emissions standards without compromising the performance or safety of vehicles.

Use in Architecture

Aluminum profiles are gaining popularity among architects and designers for creating building facades and interior structures. Customizable profiles allow for designs that not only enhance the aesthetics but also improve the functionality of buildings. Features like integrated breaks and high performance coatings contribute to better energy efficiency and sustainability.

Future Directions

Looking forward the focus in aluminum profile design is on enhancing performance promoting sustainability and broadening application possibilities. Some key trends to watch out for include;

Utilizing Additive Manufacturing; Employing 3D printing technologies to craft hybrid aluminum components with characteristics.

Smart Integration; Developing profiles embedded with sensors and smart features for data gathering and monitoring.

Bio Aluminum; Exploring the use of based materials in aluminum alloys to lessen environmental impact.

In Summary

To sum up aluminum profiles and components play a role in shaping industrial and architectural design landscapes. Progress in material science, manufacturing techniques and design innovation is propelling advancements. Expanding the reach of aluminum profile applications. With a growing emphasis on sustainability and efficiency across industries aluminum profiles are poised to remain at the forefront of progress by offering dependable solutions, for various challenges.